3d printers in Columbia DC in washington

The world of 3D printing has expanded rapidly across Washington, DC, and the Columbia area, offering hobbyists, professionals, and businesses access to cutting-edge additive manufacturing technology. Whether you're looking to purchase your first desktop 3D printer or upgrade to an industrial-grade machine, understanding the local market, available models, and pricing structures is essential. This guide explores what you need to know about acquiring and using 3D printers in the DC metropolitan area.

3D printing technology has transformed from an industrial novelty into an accessible tool for creators, educators, engineers, and entrepreneurs throughout Washington, DC, and surrounding areas. The Columbia DC region hosts numerous retailers, makerspaces, and specialty shops where individuals can explore, purchase, and learn about various 3D printing technologies. Understanding the landscape of available printers, their applications, and how to navigate the buying process can help you make informed decisions.

What Types of 3D Printers Are Available in Columbia DC

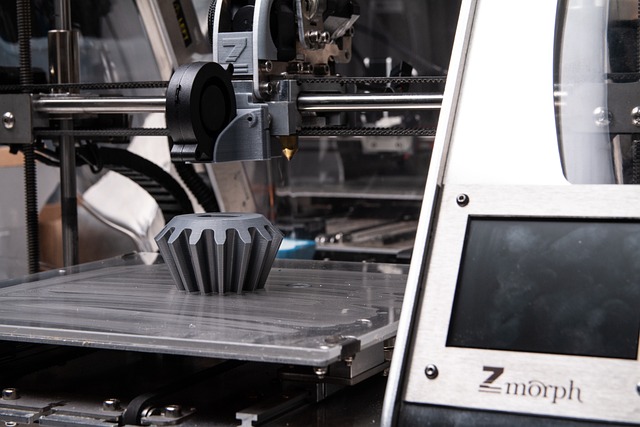

The DC metropolitan area offers access to several categories of 3D printers, each suited to different applications and skill levels. Fused Deposition Modeling (FDM) printers represent the most common and affordable option, using thermoplastic filaments to build objects layer by layer. These machines are ideal for prototyping, educational purposes, and hobby projects. Resin-based printers, including Stereolithography (SLA) and Digital Light Processing (DLP) models, provide higher resolution and smoother surface finishes, making them popular among jewelry designers, dental professionals, and miniature enthusiasts. For industrial applications, Selective Laser Sintering (SLS) and metal 3D printers are available through specialized distributors, though these typically require significant investment and technical expertise.

Where to Buy 3D Printers in Washington

Washington residents have multiple options when purchasing 3D printing equipment. National electronics retailers with locations throughout the DC area stock entry-level and mid-range consumer models, providing hands-on opportunities to examine build quality and ask questions. Specialized technology stores and maker supply shops offer curated selections with knowledgeable staff who can provide detailed technical guidance. Online retailers remain popular for accessing wider selections and competitive pricing, though buyers sacrifice the ability to physically inspect machines before purchase. Local makerspaces and fabrication labs sometimes sell refurbished or lightly used equipment, offering budget-conscious alternatives with community support included.

Key Features to Consider When Purchasing 3D Printers

Selecting the right 3D printer requires evaluating several critical specifications and features. Build volume determines the maximum size of objects you can create, with common desktop models offering platforms ranging from 150x150x150mm to 300x300x400mm. Print resolution, measured in microns, affects surface quality and detail level, with finer resolutions producing smoother results but requiring longer print times. Material compatibility varies significantly between models, with some printers limited to specific filament types while others accommodate diverse materials including flexible TPU, engineering-grade nylon, and composite filaments. Connectivity options, heated bed capability, automatic bed leveling, and enclosed build chambers represent additional considerations that impact usability and print success rates.

Understanding Costs and Pricing for 3D Printers in the Area

The cost of 3D printing equipment varies dramatically based on technology type, build volume, and feature sets. Entry-level FDM printers suitable for beginners and educational use typically range from $200 to $500, offering basic functionality with manual calibration requirements. Mid-range consumer models with enhanced features, larger build volumes, and improved reliability generally fall between $500 and $1,500. Professional-grade desktop printers with advanced capabilities, dual extrusion, or resin-based technology typically cost $1,500 to $5,000. Industrial systems designed for commercial production can exceed $10,000, with metal printing systems reaching six-figure price points. Beyond the initial purchase, ongoing costs include filament or resin materials, replacement nozzles, build surface materials, and potential maintenance or repair expenses.

| Printer Category | Example Models | Typical Price Range |

|---|---|---|

| Entry-Level FDM | Creality Ender 3, Monoprice Select Mini | $200 - $500 |

| Mid-Range FDM | Prusa i3 MK3S+, Anycubic Kobra | $500 - $1,500 |

| Resin Printers | Elegoo Mars, Anycubic Photon Mono | $200 - $800 |

| Professional Desktop | Ultimaker S5, Raise3D Pro2 | $2,500 - $6,000 |

| Industrial Systems | Formlabs Fuse 1, Markforged X7 | $10,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Local Resources and Community Support in Washington

The Washington DC area benefits from an active maker community that supports both newcomers and experienced 3D printing enthusiasts. Several makerspaces throughout the region provide access to various 3D printing technologies, training workshops, and collaborative environments where members can share knowledge and troubleshoot challenges. Universities and educational institutions often host public events, demonstrations, and courses covering 3D modeling software, printer operation, and advanced techniques. Online forums and local meetup groups connect DC-area users for knowledge exchange, group purchases of materials, and collaborative projects. These community resources can significantly flatten the learning curve and provide ongoing support as you develop your 3D printing skills.

Applications and Uses for 3D Printing Technology

3D printers serve diverse purposes across personal, educational, and professional contexts. Hobbyists create custom figurines, replacement parts for household items, and personalized gifts. Educators use 3D printing to teach design thinking, engineering principles, and bring abstract concepts into tangible form. Small businesses leverage the technology for rapid prototyping, custom manufacturing, and producing limited-run products without expensive tooling. Architects create physical models of building designs, while medical professionals use 3D printing for anatomical models, custom prosthetics, and surgical planning tools. The versatility of additive manufacturing continues expanding as materials science advances and costs decrease, making the technology increasingly accessible throughout the Columbia DC and Washington region.

Whether you’re exploring 3D printing for the first time or seeking to upgrade existing equipment, the Washington DC area offers robust resources, knowledgeable retailers, and supportive communities to help you succeed. By carefully evaluating your needs, budget, and intended applications, you can select equipment that delivers reliable performance and opens creative possibilities.