3D Printers & Scanners

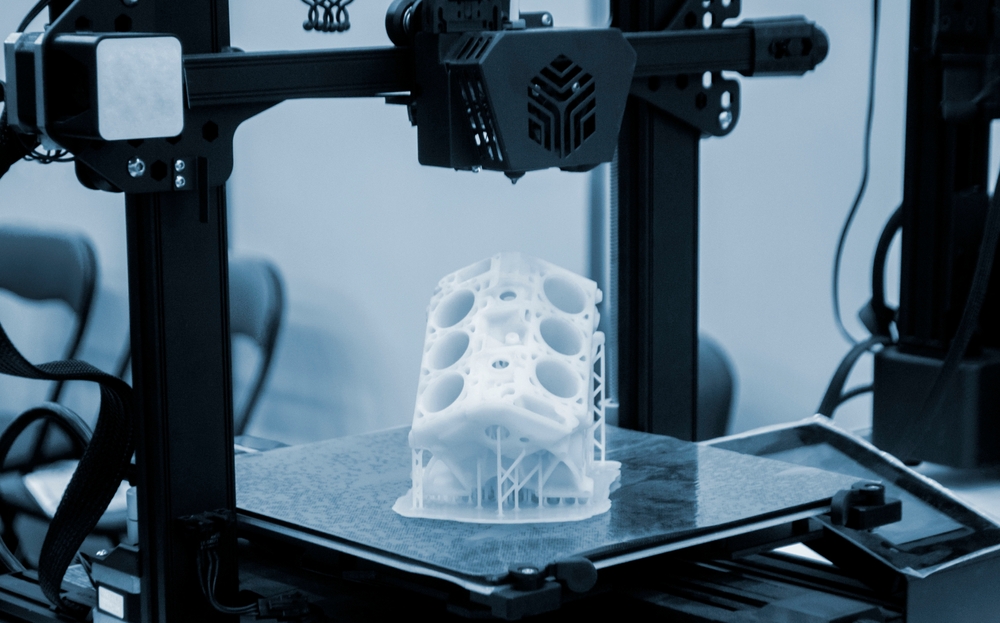

A 3D printer is a device that creates three-dimensional objects by depositing material layer by layer based on a digital model. Modern 3D printers support a wide variety of materials, including plastics, resins, metals, and composites, making them suitable for prototyping, manufacturing, and end-use production. 3D scanners, on the other hand, capture the physical geometry of real-world objects and convert them into digital 3D models. When combined, these technologies allow users to copy, modify, and reproduce objects with remarkable precision and efficiency.

3D printing technology has evolved from industrial applications to accessible home use, enabling anyone to transform digital designs into physical reality. Combined with 3D scanners, these tools create a complete workflow for capturing, modifying, and reproducing objects with remarkable precision. This article explores how these technologies work, their practical applications, and what you need to know before investing in either device.

How Do 3D Printers Transform Digital 3D Models Into Physical Objects?

3D printers build objects layer by layer from digital files, typically using materials like plastic filament, resin, or metal powder. The process begins with a 3D model created in design software or downloaded from online repositories. The printer reads this file and deposits material according to precise coordinates, gradually constructing the object from bottom to top. Different printing technologies exist, including Fused Deposition Modeling (FDM), which melts plastic filament, and Stereolithography (SLA), which uses light to cure liquid resin. Each method offers distinct advantages in terms of speed, detail, and material compatibility. The ability to produce complex geometries impossible with traditional manufacturing makes 3D printing invaluable for prototyping, custom parts, and small-batch production.

What Can You Create and Copy With 3D Scanning Technology?

3D scanners capture the physical dimensions and surface details of real-world objects, converting them into digital 3D models that can be modified or reproduced. These devices use various technologies, including laser triangulation, structured light, and photogrammetry, to measure thousands of points on an object’s surface. The resulting point cloud data is processed into a mesh that accurately represents the original item. This technology proves particularly useful for reverse engineering, quality control, archival preservation, and creating custom-fit products. You can scan anything from small mechanical parts to entire rooms, though accuracy and resolution vary based on scanner quality and object characteristics. Once digitized, these models can be edited in 3D software before printing, allowing you to copy existing objects or modify them to suit specific needs.

How Can You Modify Scanned Objects Before Printing?

After scanning an object and generating a digital 3D model, specialized software allows you to modify the design before printing. CAD programs and mesh editing tools enable you to adjust dimensions, add features, remove imperfections, or combine multiple scanned elements into a single design. Common modifications include scaling objects to different sizes, hollowing solid parts to reduce material usage, adding mounting holes or connectors, and repairing damaged areas of scanned items. The editing process requires some learning, but many user-friendly applications now offer intuitive interfaces for basic modifications. Advanced users can perform complex operations like topology optimization, surface smoothing, and parametric adjustments. This capability to modify scanned objects bridges the gap between physical and digital worlds, enabling customization that would be difficult or impossible with traditional manufacturing methods.

What Are the Practical Applications for Creating Physical Objects?

The combination of 3D printing and scanning serves numerous practical purposes across industries and hobbies. In manufacturing, companies use these tools for rapid prototyping, allowing designers to test physical versions of products before committing to expensive tooling. Medical professionals create custom prosthetics, dental appliances, and surgical guides tailored to individual patients. Educators use 3D printing to produce teaching aids and allow students to interact with physical representations of abstract concepts. Hobbyists and makers produce replacement parts for broken items, custom tools, artistic sculptures, and personalized gifts. Architects build scale models of buildings and urban developments. Restoration specialists scan and reproduce damaged historical artifacts. The technology also supports on-demand manufacturing, reducing inventory costs and enabling localized production of spare parts.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Entry-Level FDM Printer | Creality, Anycubic | $200-$400 |

| Mid-Range Resin Printer | Elegoo, Phrozen | $300-$600 |

| Professional FDM Printer | Prusa, Ultimaker | $800-$3,000 |

| Handheld 3D Scanner | Revopoint, Creality | $200-$800 |

| Desktop Structured Light Scanner | Shining 3D, Matter and Form | $1,000-$5,000 |

| Professional Laser Scanner | Artec, Faro | $10,000-$50,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

What Should You Consider Before Investing in These Technologies?

Before purchasing 3D printers or scanners, evaluate your specific needs and technical capabilities. Consider what types of objects you plan to create or copy, as this determines the required print volume, resolution, and material compatibility. FDM printers offer affordability and ease of use but produce visible layer lines, while resin printers deliver smoother surfaces at the cost of messier post-processing. Build volume matters if you need to produce large objects, though most home printers accommodate items up to 20-30 centimeters. For scanning, determine whether you need color capture, high precision for small parts, or the ability to scan large objects. Software compatibility is crucial, as you’ll need programs to process scans, modify models, and prepare files for printing. Factor in ongoing costs including materials, replacement parts, and potential software subscriptions. The learning curve varies, with entry-level devices becoming increasingly user-friendly while professional equipment demands technical expertise.

The convergence of 3D printing and scanning technologies empowers individuals and organizations to bridge the physical and digital realms with unprecedented ease. Whether you’re looking to copy existing objects, modify designs to meet specific requirements, or create entirely new items from digital 3D models, these tools offer flexibility that traditional manufacturing cannot match. As the technology continues to advance and prices decrease, the ability to produce custom physical objects on demand will become increasingly accessible, transforming how we approach design, production, and problem-solving in countless applications.