3D Printers & Scanners

There are several types of 3D printers available for purchase, each designed for different use cases. Fused Deposition Modeling (FDM) printers are the most common and affordable option, ideal for beginners, educational environments, and general prototyping. Stereolithography (SLA) and Digital Light Processing (DLP) printers offer higher resolution and smoother surface finishes, making them popular in dental, jewelry, and medical applications. Selective Laser Sintering (SLS) and metal 3D printers are typically used in industrial environments where strength, durability, and complex geometries are required. Understanding these technologies is crucial when deciding which printer best matches your needs.

Three-dimensional printing and scanning represent revolutionary technologies that bridge the gap between digital design and physical creation. These tools have evolved from expensive industrial equipment to accessible consumer devices, opening new possibilities for manufacturing, education, healthcare, and creative projects.

Understanding 3D Printing Technology

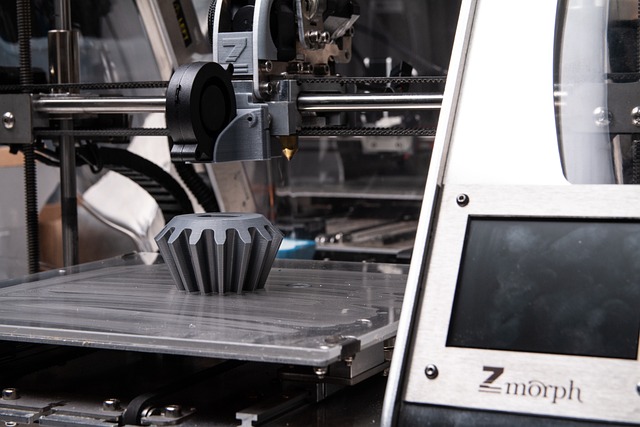

Three-dimensional printers create physical objects by building them layer by layer from various materials. The process begins with a digital 3D model, which specialized software slices into hundreds or thousands of thin horizontal layers. The printer then deposits material according to each layer’s pattern, gradually building the complete object from bottom to top.

Different printing technologies use various approaches to material deposition. Some melt plastic filaments and extrude them through heated nozzles, while others cure liquid resins with ultraviolet light or bind powder particles with adhesives or lasers. Each method offers distinct advantages depending on the intended application, material requirements, and desired surface finish.

Fused Deposition Modeling Explained

Fused Deposition Modeling represents one of the most popular and accessible 3D printing technologies. This method works by heating thermoplastic filaments to their melting point and extruding the molten material through a precisely controlled nozzle. The heated material bonds with previously deposited layers as it cools, creating strong adhesion between layers.

FDM printers offer several advantages including relatively low costs, wide material compatibility, and user-friendly operation. Common materials include PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), PETG (polyethylene terephthalate glycol), and specialized filaments containing wood fibers, metal particles, or carbon fiber for enhanced properties.

Types of 3D Printers and Their Applications

Modern 3D printers fall into several categories based on their printing technology and intended use. Desktop FDM printers dominate the consumer market due to their affordability and ease of use. These machines excel at creating prototypes, educational models, household items, and artistic projects using thermoplastic materials.

Resin-based printers use stereolithography (SLA) or digital light processing (DLP) to cure photopolymer resins with precise light patterns. These printers achieve exceptional detail and smooth surface finishes, making them ideal for jewelry, miniatures, dental models, and applications requiring fine features.

Industrial printers employ advanced technologies like selective laser sintering (SLS), which uses lasers to fuse powder particles, or metal printing systems that work with titanium, aluminum, and steel powders. These high-end machines serve aerospace, automotive, medical device manufacturing, and other demanding applications.

3D Scanning Technology and Methods

Three-dimensional scanners capture the geometry, texture, and sometimes color information of real-world objects, converting them into digital 3D models. Various scanning technologies serve different needs and budgets, from smartphone apps using photogrammetry to professional laser scanners providing micron-level accuracy.

Structured light scanners project known patterns onto objects and analyze the deformation of these patterns to calculate surface geometry. These systems offer good accuracy and speed for medium-sized objects. Laser scanners use time-of-flight or triangulation methods to measure distances precisely, creating highly accurate point clouds that represent object surfaces.

Photogrammetry techniques reconstruct 3D models from multiple photographs taken from different angles. While requiring more processing time, this approach uses standard cameras and can capture large objects or environments that would be impractical for other scanning methods.

| Product Category | Example Providers | Key Features | Cost Estimation |

|---|---|---|---|

| Entry-level FDM Printers | Creality, Prusa, Bambu Lab | Easy setup, PLA/ABS compatibility | $200-800 |

| Professional FDM | Ultimaker, Markforged, Stratasys | Multi-material, enclosed chambers | $2,000-15,000 |

| Resin Printers | Formlabs, Anycubic, Elegoo | High detail, smooth finish | $300-5,000 |

| 3D Scanners | Artec, Shining 3D, Revopoint | Portable, various accuracy levels | $500-50,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Software and Workflow Considerations

Successful 3D printing and scanning require appropriate software tools for design, file preparation, and device control. Computer-aided design (CAD) programs like Fusion 360, SolidWorks, or free alternatives like Blender and Tinkercad enable users to create original 3D models or modify existing designs.

Slicing software converts 3D models into printer-specific instructions, allowing users to adjust parameters like layer height, infill density, support structures, and printing speed. Popular slicers include PrusaSlicer, Cura, and proprietary solutions from printer manufacturers.

Scanning workflows typically involve capturing raw data, processing it to create clean 3D models, and potentially preparing files for 3D printing. This process may require specialized software for point cloud processing, mesh repair, and model optimization.

Future Developments and Industry Trends

The 3D printing and scanning industry continues evolving rapidly, with improvements in speed, accuracy, material options, and ease of use. Multi-material printing capabilities allow single objects to incorporate different properties, colors, or functions. Larger build volumes enable printing of furniture, architectural components, and even entire structures.

Metal 3D printing advances are revolutionizing aerospace and medical industries, while bioprinting research explores printing with living cells for tissue engineering applications. Scanning technology is becoming more accessible through smartphone integration and AI-powered processing that simplifies complex workflows.

As these technologies mature, they increasingly integrate into traditional manufacturing processes, educational curricula, and creative workflows. Understanding their capabilities and limitations helps users harness their potential for innovation, customization, and rapid prototyping across diverse applications.