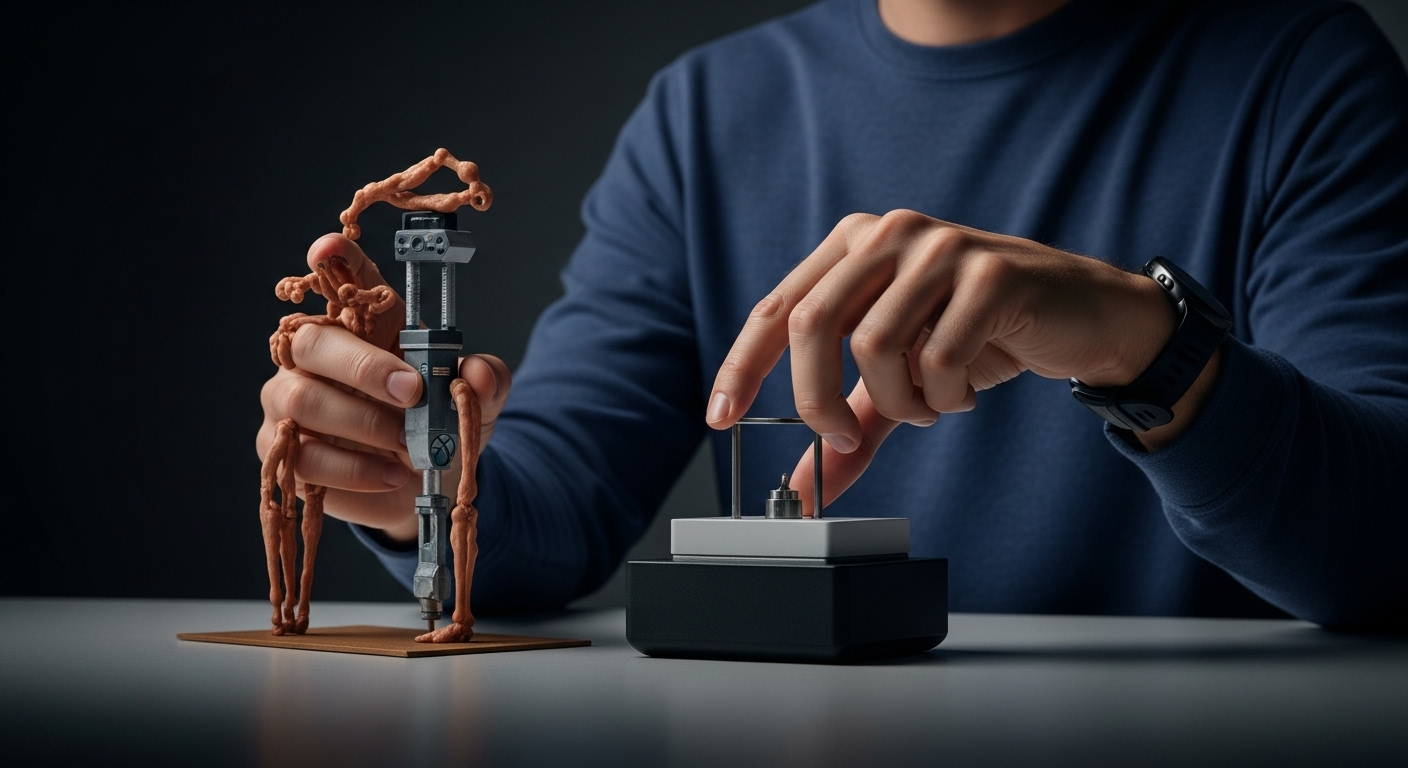

Peter Dilworth 3d pen

The 3Doodler is a 3D pen developed by Peter Dilworth, Maxwell Bogue, and Daniel Cowen of WobbleWorks, Inc. The 3Doodler works by extruding heated plastic that cools almost instantly into a solid, stable structure, allowing for the free-hand creation of three-dimensional objects.

The world of 3D pens has seen remarkable innovation in recent years, with various inventors and entrepreneurs contributing to their development. These handheld devices allow users to draw in three dimensions, creating sculptures, prototypes, and artistic works that extend beyond traditional two-dimensional surfaces.

Understanding Peter Dilworth’s Role in 3D Pen Development

Peter Dilworth has been involved in advancing 3D pen technology, focusing on making these tools more accessible and user-friendly. His contributions have centered on improving the precision and reliability of 3D pens, addressing common issues that early adopters faced with temperature control and material flow. Dilworth’s work has emphasized creating devices that maintain consistent performance while remaining intuitive for users of all skill levels.

The technical improvements associated with his involvement include enhanced heating mechanisms, better material compatibility, and more ergonomic designs. These advances have made 3D pens more practical for extended use and have expanded their appeal beyond hobbyists to include professional designers and educators.

How 3D Pen Technology Functions

3D pens operate by heating plastic filament to its melting point and extruding it through a heated nozzle. Users can control the flow rate and temperature, allowing for precise application of the melted material. The plastic cools and hardens quickly upon extrusion, enabling the creation of stable three-dimensional structures.

Modern 3D pens support various filament types, including PLA, ABS, and specialty materials with unique properties. Temperature control systems ensure consistent melting and flow, while adjustable speed settings provide users with greater control over their creative process. These features make 3D pens versatile tools for artistic expression, prototyping, and educational applications.

Creative Applications and Uses

3D pens have found applications across numerous fields, from artistic creation to practical problem-solving. Artists use them to create sculptures, jewelry, and decorative objects that would be difficult or impossible to achieve with traditional tools. The ability to draw in mid-air opens up entirely new possibilities for creative expression.

In educational settings, 3D pens help students visualize complex concepts in subjects like geometry, engineering, and art. Teachers use them to create interactive learning materials and encourage hands-on exploration of three-dimensional relationships. The immediate tactile feedback helps students better understand spatial concepts and design principles.

Professional applications include rapid prototyping, architectural modeling, and repair work. Designers can quickly create physical representations of their ideas, test form factors, and make iterative improvements. The portability of 3D pens makes them valuable tools for field repairs and on-site modifications.

Technical Specifications and Features

Modern 3D pens incorporate several key features that enhance their usability and performance. Temperature control systems typically range from 160°C to 230°C, accommodating different filament types and their specific melting requirements. Variable speed controls allow users to adjust extrusion rates based on their project needs and skill level.

Ergonomic design considerations include lightweight construction, comfortable grip areas, and intuitive button placement. Many models feature LCD displays that show temperature and speed settings, providing users with precise control over their creative process. Safety features such as automatic standby modes and heat-resistant nozzles help prevent accidents during use.

| Feature | Entry-Level Models | Professional Models | Cost Estimation |

|---|---|---|---|

| Temperature Range | 160-200°C | 160-230°C | $30-60 |

| Speed Control | Basic 2-3 Settings | Variable Digital Control | $60-120 |

| Display | LED Indicators | LCD Screen | $80-150 |

| Filament Compatibility | PLA Only | PLA, ABS, Specialty | $100-200 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Safety Considerations and Best Practices

Using 3D pens safely requires understanding their operating temperatures and following proper handling procedures. The nozzle and extruded material can reach temperatures that may cause burns, making careful handling essential. Users should work in well-ventilated areas, especially when using ABS filaments that may produce fumes during heating.

Proper maintenance includes regular cleaning of the nozzle and feeding mechanism to prevent clogs and ensure consistent performance. Storing filaments in dry conditions helps maintain their quality and prevents printing issues. Following manufacturer guidelines for temperature settings and filament compatibility ensures optimal results and extends device lifespan.

The evolution of 3D pen technology continues to expand creative possibilities while making these tools more accessible to diverse users. Whether for artistic expression, educational purposes, or practical applications, 3D pens represent a unique intersection of technology and creativity that empowers users to bring their three-dimensional visions to life.