3D Printers & Scanners: Complete Guide for Smart Purchasing Decisions

3D printers and 3D scanners have become essential tools across a wide range of industries, from engineering and manufacturing to education, healthcare, and creative design. What was once considered experimental technology is now a practical investment for businesses and individuals looking to accelerate product development, improve accuracy, and reduce production costs. Buying the right 3D printer or scanner requires a clear understanding of your goals, budget, and technical requirements. This guide will help you explore available options, key features, and important considerations before making a purchase.

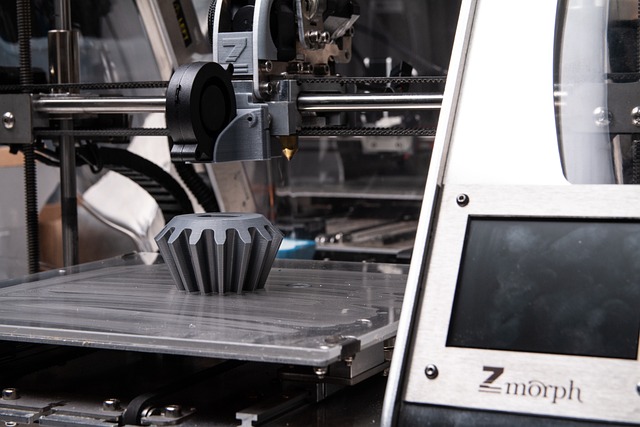

Understanding 3D Printer Technology

A 3D printer operates by building three-dimensional objects layer by layer from a digital design. Various technologies underpin these devices, each with distinct advantages and applications. Fused Deposition Modeling (FDM) is perhaps the most common, utilizing thermoplastic filaments heated and extruded through a nozzle to create layers. Stereolithography (SLA) and Digital Light Processing (DLP) printers use liquid resin cured by a light source, known for producing highly detailed objects with smooth finishes. Selective Laser Sintering (SLS) printers employ a laser to fuse powdered materials, offering robust parts with complex geometries. The choice of technology often depends on the desired material properties, print resolution, and the intended use of the final product.

Selecting the right 3D printer involves considering factors such as print volume, material compatibility, and overall print speed. Larger print volumes allow for bigger objects or multiple smaller objects in a single batch, while material compatibility dictates the range of applications, from prototypes to functional parts. The speed of a 3D printer can impact workflow, especially for those with high production demands. Each type of 3D printer offers a unique balance of these attributes, catering to different user requirements and project scales.

Essential Guide to 3D Scanning

3D scanning is the process of analyzing a real-world object or environment to collect data on its shape and appearance, which is then used to construct digital three-dimensional models. This technology serves a multitude of purposes, including reverse engineering, quality control, cultural heritage preservation, and creating custom products. There are several methods for 3D scanning, each with its own set of principles and suitable applications. Structured-light scanners project patterns onto an object and analyze the deformation of these patterns to calculate depth and shape. Laser scanners use a laser beam or line to measure distances to the object’s surface.

Photogrammetry, another popular method, involves taking multiple photographs of an object from different angles and using software to reconstruct a 3D model. Handheld scanners offer portability and flexibility, ideal for scanning larger objects or in varied environments, while desktop scanners provide higher precision for smaller items. The accuracy, speed, and ease of use are key considerations when choosing a 3D scanning solution. Understanding the specific needs of a project, such as the required level of detail or the size of the objects to be scanned, will guide the selection process for the most appropriate scanning technology.

What a 3D Scanner Requires for Optimal Performance

For a 3D scanner to perform optimally, several requirements must be met, ranging from hardware specifications to environmental conditions and software capabilities. High-quality hardware, including cameras and projection systems, is fundamental for capturing accurate data. The resolution of the scanner, often measured in points per scan or polygon count, directly influences the level of detail that can be captured. Software is equally vital, as it processes the raw data into a usable 3D model, handles meshing, texture mapping, and allows for editing and optimization of the scanned object.

Environmental factors can also significantly impact scanning results. Stable lighting conditions, free from harsh shadows or glare, are often necessary for optical scanners. The surface properties of the object being scanned, such as reflectivity or transparency, may require pre-treatment, like applying a matte spray, to ensure accurate data capture. Additionally, a stable and powerful computer system is often required to run the processing software efficiently, especially for large datasets. Understanding these requirements helps users prepare their scanning environment and workflow for the best possible outcomes.

Cost Insights for 3D Printers and Scanners

The investment in 3D printing and scanning technology can vary widely, reflecting the diversity in features, capabilities, and target markets. Entry-level FDM 3D printers can be acquired for a few hundred US dollars, suitable for hobbyists and educational purposes. Mid-range SLA or more advanced FDM printers typically range from around $1,000 to $5,000, offering improved precision, larger build volumes, and more material options. Professional and industrial-grade machines, including SLS or metal 3D printers, can cost tens of thousands to hundreds of thousands of US dollars, reflecting their advanced capabilities and specialized applications. Similarly, 3D scanners range from smartphone-based apps for minimal cost to professional handheld or desktop scanners costing several thousands of US dollars, with high-end industrial systems reaching into the tens of thousands.

| Product/Service | Provider | Cost Estimation (USD) |

|---|---|---|

| Ender 3 Pro (FDM 3D Printer) | Creality | $200 - $300 |

| Mars 3 Pro (Resin 3D Printer) | ELEGOO | $250 - $350 |

| Prusa i3 MK3S+ (FDM 3D Printer) | Prusa Research | $750 - $1,100 |

| EinScan SP (Desktop 3D Scanner) | Shining 3D | $2,000 - $2,500 |

| Form 3+ (SLA 3D Printer) | Formlabs | $3,500 - $4,500 |

| Artec Eva (Handheld 3D Scanner) | Artec 3D | $20,000 - $30,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Conclusion

Navigating the landscape of 3D printers and scanners involves understanding the underlying technologies, their specific applications, and the practical requirements for their operation. From the various methods of additive manufacturing to the diverse techniques of digital capture, each device offers unique advantages for different projects and budgets. By carefully considering factors such as precision, speed, material compatibility, and overall cost, individuals and organizations can make well-informed decisions, ensuring their investment in 3D technology effectively meets their creative and functional objectives.